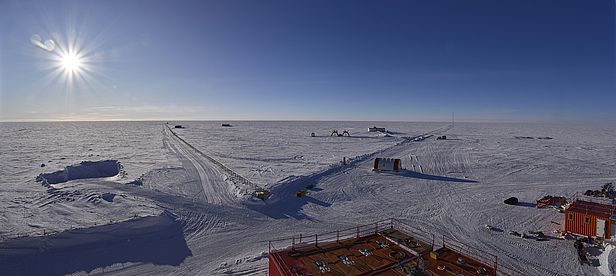

25.01.2024 | Matthias Jaggi | SLF News

SLF technician Matthias Jaggi reports on his expedition to the Antarctic. Part three: lugging crates, digging holes and penal labour.

I'm shocked to realise it's been almost a month since my last blog post. Time passing quickly is usually a good sign with me. Looking back, that also applies in this case, although there have been a few days when the expedition blues have peeked out from behind the corner of the station. Yes, even if, like me, you have the privilege of working in such a unique, isolated and breathtaking part of the world, you sometimes have to give yourself a kick up the backside, and the trudge to the snow profile feels harder on some days than others. At such times, it helps if I break up the daily routine with a little something out of the ordinary, to make me feel that I can do my own thing – whether it be skipping dinner and making my own muesli later, running across the square in my shorts without a walkie-talkie and feeling the biting cold, or (for the third time now) baking brioche for breakfast. The chef was a little sceptical at first, but the Italians and French like sweet food in the morning, so it went down well. So much so that I now have to bake as a punishment if I mess something up at the station.

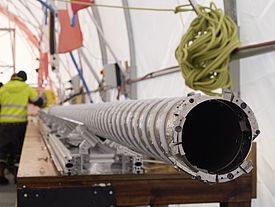

After a trip of almost two weeks, the traverse from Dumont d'Urville arrived at Dome C in the first week of December, bringing the rest of my research material with it. So I immediately set about sealing the snow samples taken from the snow profile at the end of November. We plan to examine the microstructure of these samples using the CT scanner in Davos. I'd like to briefly explain why and how we seal snow samples. Imagine packing a snow sample in a box, sticking a stamp on it and sending it halfway around the world. At best, the postman will end up delivering a soggy cardboard box. So that won't work!

Even if you could keep checking to make sure the snow sample remained chilled throughout the journey, experience shows that maintaining perfect refrigeration over a distance of 15,000 kilometres, with transshipment, is something of a pipe dream. Quick aside: even though my hands often freeze like hell in the snow profile, snow is physically an extremely hot and therefore changeable material. It's hot because the temperature of the snow material, even here, in one of the coldest regions on earth, is close to its melting point ("high homologous temperature" is the jargon term). Steel, for example, which is far from its melting point at the temperatures usually found on earth (low homologous temperature), does not actually change its structure and physical properties.

Shipping snow ¶

Affordable refrigerated transport cannot reduce the homologous temperature of snow to such an extent that no microstructural changes would occur. This is where sealing comes in. If we fill the pore space between the snow crystals, we prevent water molecules from sublimating away from the crystal surface, redepositing elsewhere and thus changing the structure. Obviously, the sealing liquid has to have a few special properties. For example, it must be just liquid below the freezing point, must not dissolve ice chemically and should then be frozen at minus twenty degrees Celsius. Sealing preserves the snow microstructure, meaning that even months later we can use a CT scanner to measure what the condition of the snow profile was here.

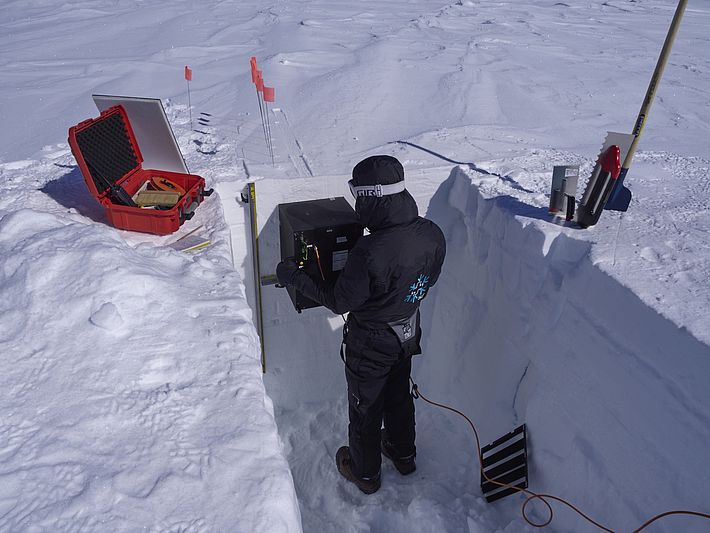

Christmas and New Year have come and gone, but luckily no one will be interested in that any more in mid-January so I can move on to my mid-season snow profile with an easy conscience. The plan was to make this two and a half metres deep. That is already deep enough that you need to incorporate a step when digging, otherwise it's virtually impossible to chuck the snow out of the hole by hand. Which we duly did – and for added fun, my volunteer assistant decided to time us. So we dug away like tigers and after 58 minutes, completely out of breath, reached the desired depth. Snow profiling is almost like a biathlon: you might be completely exhausted from the digging, but you then need the utmost concentration and precision when characterising the snow and using the measuring devices.

Prototype under test ¶

As well as the tried-and-tested measuring methods, I also have a prototype device with me that I've been putting through its paces. This was developed with financial support from the Swiss Innovation Agency, Innosuisse, whose remit is to translate knowledge derived from research, in collaboration with industry, into market-ready applications accessible to a (relatively) wide public. The SLF's SnowImager will make it possible for the first time to measure a snow profile over a large area in two dimensions. The methods used up to now essentially involve taking point measurements, which with some effort can be combined to form a one-dimensional profile. In the Alps, where the snow layers are usually fairly horizontal and relatively homogeneous, a vertical, one-dimensional profile already represents the snowpack reasonably well. But the SnowImager allows you to measure in two dimensions. Again, some effort is required, but by measuring profile after profile, you effectively end up with the three-dimensional spatial structure of the snowpack. Since the Antarctic snowpack is formed less by precipitation and more by wind transport, its layering is very inhomogeneous. In order to carry out a clean, physical characterisation, the second and third dimensions are actually essential. Thanks to our industrial partner Davos Instruments AG, the SnowImager prototype is already in a very usable condition, which is not always the case with prototypes. But when you're working in windy conditions, in temperatures that feel like minus fifty degrees Celsius and with cold fingers, you soon find out where the design needs to be tweaked once you get back to your nice warm office. So I also have a little side-project in addition to my main reason for being here, but one that will definitely help to improve our understanding of Antarctic snowpack processes.

In addition, once a week we transport boxes of ice cores from Little Dome C (Beyond EPICA project) to Dome C. Half of the ice cores are placed underground here at Dome C for long-term storage, the other half will be packed in refrigerated containers at the end of the season and shipped to various laboratories in Europe for further study. Volunteers are always needed to help unload boxes. For me this makes a welcome change.

Soon it'll be time to pack up... but more on that later.

Already published: ¶

- Part 1: the arrival

- Part 2: free at last!