Ice and snow tribometer ¶

One of the key equipment items of the ski laboratory is the ice and snow tribometer. It is used to measure the sliding properties of various materials and surfaces. In practice, we use it to test the sliding characteristics on snow of running surfaces, waxes, and diverse ground and treated surfaces.

The tribometer measures the coefficient of friction between the substrate (in our case usually snow or ice) and a certain material (e.g. ski bases, skins, runners for sleds, or various base treatments). It allows us to conduct reproducible measurements in controlled and consistent outline conditions. Testing can take place without any reliance on the seasons, test pilots/skiers and weather conditions. Material tests can therefore be performed at a lower cost.

Set-up ¶

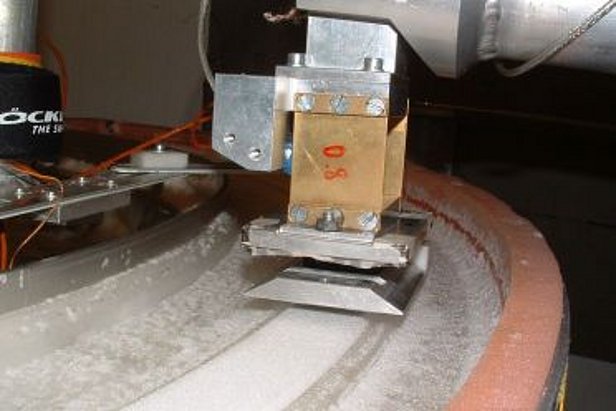

A measuring routine entails pressing a material sample against the rotating substrate (Fig. 1) and determining the friction.

The ice and snow tribometer consists of a rotating table with a diameter of 1.80 m and two separate arms. One of these serves the purpose of preparing the sliding surface, and the other presses the sample against the surface by way of a biaxial linear drive. The measured variables are normal force (by strain gauge) and friction (piezoelectric measurement). The sliding speed is variable between 0.5 and 20 m/s, and the temperature can be regulated between -20 °C and 0 °C. We can prepare a variety of sliding surfaces, namely smooth or structured ice, or snow. The ice or snow temperature is measured by two infrared sensors.